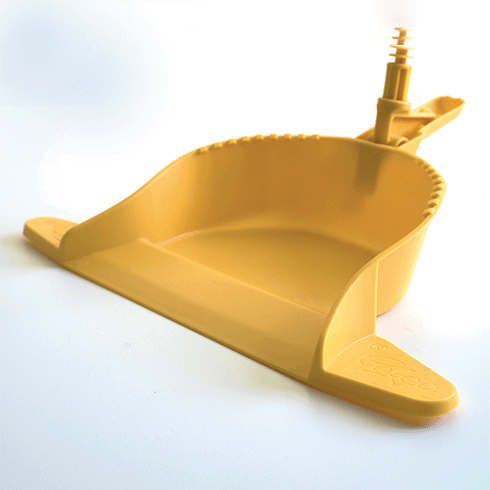

Economic mold

This mould tooling technology enables you to validate the design of your prototype parts before setting in motion the production progress.

Read more

Read more

Economical

A prototype tooling technology at controlled cost.

Small series

Compact injection-moulded parts using the minimum quantities required for validation.

Production-grade material

Serves to test the properties of a product in its final material.

Produce and test your prototypes

Economic solution

This mould tooling technology enables you to validate the design of your prototype parts before launching production resources.

During the validation phase of your parts, take advantage of good material prototypes to :

- Test the characteristics of the product in its final material.

- Carry out your mechanical validations: assembly, strength, operation.

A real cost-effective alternative that allows you to benefit from your parts in good quality.

Ideal production for your prototype parts.

- Make and test prototypes,

- Need the final material,

- Get parts quickly,

- Validate the design before launching production resources.

Technical expertise

From 1,000 to 10,000 injection-moulded parts

- Economic mold

-

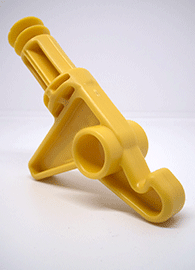

Economic mold

The economic mold, via our Chinese partner, enables you to reduce the production costs of your prototype parts. A real alternative for parts injected in several thousand copies.

Download the brochureSpecifications- Mould type: metal mould.

- Non-export mold.

Final material- All thermoplastics except PVC.

Dimensions- Part size according to analysis and technical validation.

- Max volume = <200cm3.

- Max. surface area = <300cm2.

Production lead times- Approximately 4 to 6 weeks for the first parts.

Comparison of tooling technologies

Do you know if economic molds are suited to producing your plastic parts?

View our comparison or why not get in touch with us.