Discover Abaqus: Our new asset in digital simulation

Advanced expertise with ABAQUS® software

Initial has added ABAQUS® from 3DS (Dassault Systems) to its range of digital services. The performance and reliability of ABAQUS® make it a benchmark in finite-element digital simulation.

“This development is part of our growing collaboration with Avenao®, a recognised distributor of 3DS solutions, and marks a decisive step towards greater operational and technological synergy.”

Product innovation and optimisation

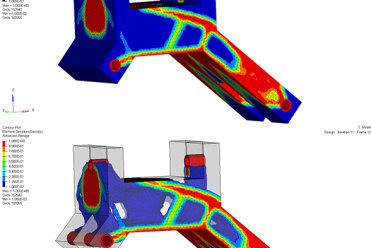

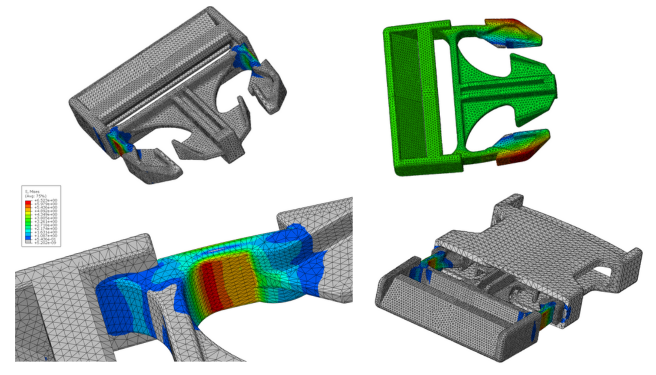

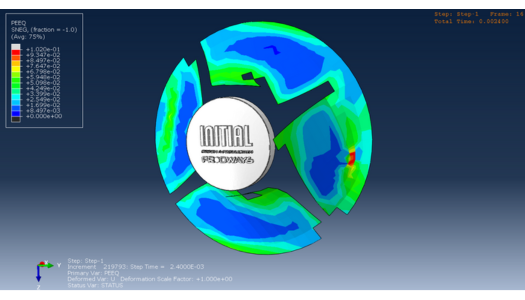

Case studySimulating the mechanical behaviour of a polyamide bag loop/quick fastener.

Transient analysis, observation of how the fastener works, and the mechanical stresses generated during insertion.

Von Mises stress maps in MPa.

The von Mises stress calculation is used in engineering to assess and represent the resistance of materials to warping and breakage. It is particularly useful for ductile materials, which can warp considerably before breaking.

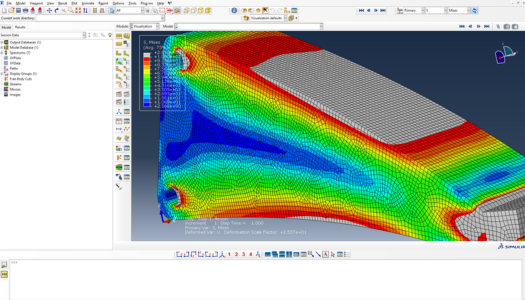

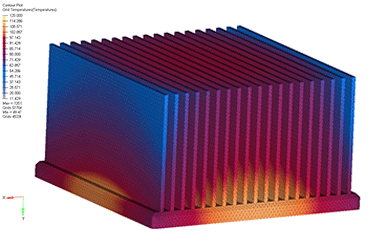

Advanced post-processing functions

The interface makes it easy to prepare simulation models, configure analyses, and interpret results. Post-processing tools allow for detailed visualisation and in-depth analysis of the results, helping to quickly identify areas that need adjustment or improvement.

Incorporating Static and Dynamic Simulations

With ABAQUS®, it is possible to conduct both static analyses to assess strength and warping under one or more loads as well as dynamic simulations to see how materials or structures behave under loads that vary over time.

Its proven robustness in calculating structures, in both implicit mode with ABAQUS®Implicit and explicit mode with ABAQUS®Explicit, is reinforced by algorithms that are regularly optimised for maximum accuracy and efficiency.

Software interoperability

ABAQUS® integrates easily with our CAD software (Creo®, Catia® and SolidWorks®) to simplify the design and analysis workflow.

The interoperability between ABAQUS® and SolidWorks® paves the way for integrated and optimised design and analysis processes.

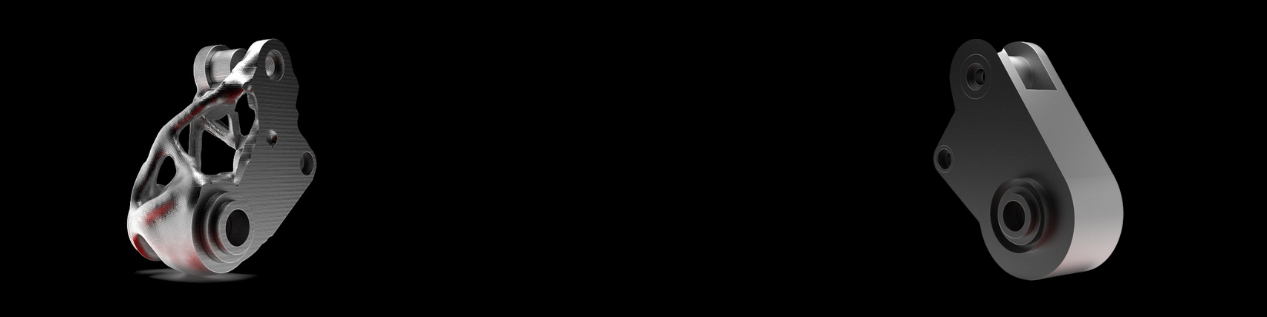

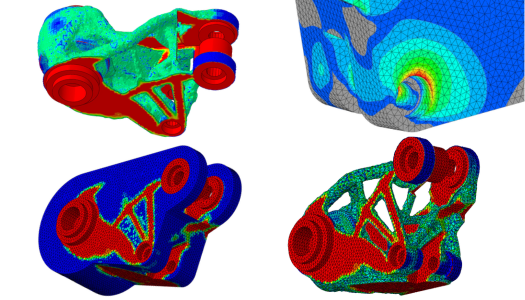

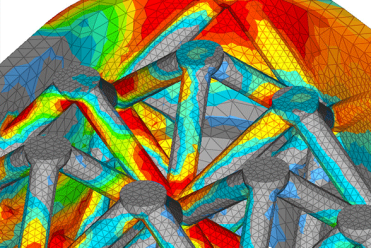

Topology optimisation

By enhancing its range of digital simulations with ABAQUS®, INITIAL is boosting its topological optimisation capabilities with the TOSCA® solver encapsulated in ABAQUS®. Initial continues to offer these topological optimisation solutions. This technology directly links to additive manufacturing, which is the only way of creating the complex shapes produced by the algorithm.

Backed by its experience in 3D printing and the topological optimisation solutions available on the market, Initial ensures complete control of the digital process, right through to the production of your prototypes.

An example of the topological optimisation of a key part of an articulated robot arm.

Element density map (the elements that are not essential to the rigidity of the structure are in blue, while the elements that are crucial to the mechanical strength of the structure are shown in red).

A strategic change

By integrating this software into our product design department, INITIAL demonstrates its commitment to providing solutions that meet the highest standards of digital simulation and computer-assisted design, a reflection of its ambition for excellence in industrial product design.

Digital simulation

Discover our services

Thermal, mechanical and fluid simulation

Discover our services