Mahi prosthetic foot: plastic injection moulding

Who is EXONEO ?

Biomechanics & industrial design.From this exchange, EXONEO was born in February 2017 with the desire to answer the question:

What if biomechanical engineering, inspired by the way the human body works, could design innovative prosthetics and orthotics?

moulage injection plastique

Innovative MedTech startup

Encouraged by Joëlle’s words, Exoneo was convinced of the merits of its innovation and devoted its energy to a mission: to revolutionize the biomechanical response to disability by designing prosthetic and orthotic products that are innovative, comfortable and accessible to all.

Specialized in biomechanical engineering

Convinced that biomechanics can significantly improve the quality of life of people with motor disabilities, all Exoneo employees are committed to offering solutions that take into account the different aspects of their lives: mobility, comfort, practicality, durability and affordability.

All Exoneo products are anatomically inspired, developed for you and accessible to all.

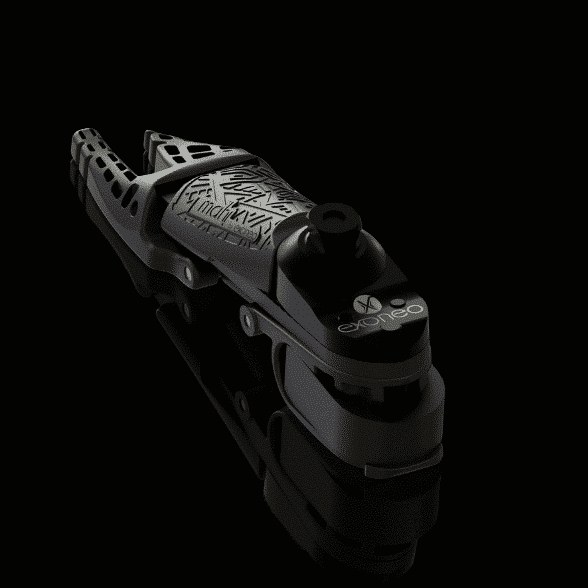

The Mahi project

Encouraged by Joëlle’s words, Exoneo was convinced of the merits of its innovation, and devoted its energies to a mission: to revolutionize the biomechanical response to disability by designing prosthetic and orthotic products that are innovative, comfortable and accessible to as many people as possible.

This approach enabled us to launch our first product: Upya (which means “new start” in Swahili). Upya offers natural walking sensations and comfort. However, with Upya, the level of mobility, eligible patient weights and available sizes were limited (not very active patients, weights between 55 and 110 kgs and sizes between 25cm and 29cm).

“Mahi is the pure expression of biomechanics at the service of people seeking renewed freedom of movement.”

A prosthetic foot

We called it Mahi (which means « performance » in Maori language). Upya was our first born, Mahi is our prodigy. Mahi is what we do best today.

The aim of the Mahi foot was to offer the most dynamic patients unprecedented walking comfort coupled with a dynamism that matches their activity. The aim is that they should no longer have to adapt to a prosthetic foot, but that the prosthetic foot should adapt to their lifestyle. So the idea here was to broaden the patient target: from 40 to 110kgs (soon 130kgs) and sizes from 21 cm to 29 cm.

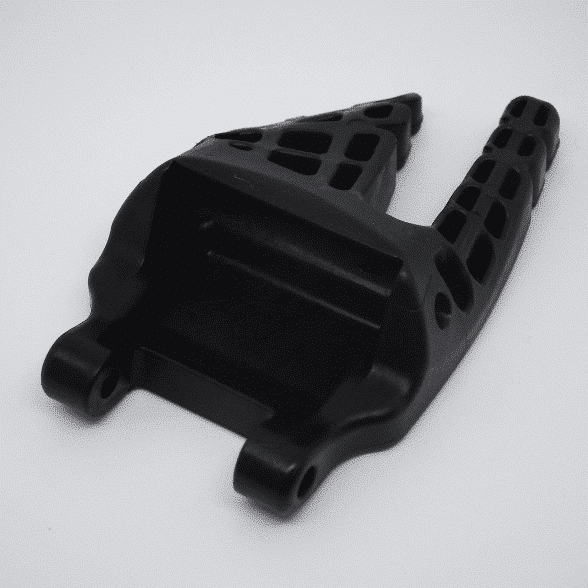

Product development

Meeting this challenge requires a different approach to product development. Because our approach to prosthetic product development is unique, we have to choose prototyping and production solutions that are in line with our philosophy. A biomechanical prosthetic foot based on the human foot means a prosthetic foot containing several parts assembled and manufactured on a large scale.

Initial & EXONEO

Working with Initial not only allows us to reduce our environmental impact by choosing a close partner, but also to benefit from French know-how. Moreover, Initial offers a wide range of solutions, from mold design to part injection. From 3D printing for mock-ups and prototypes to polymer injection for mass-produced parts, we can work hand in hand to offer patients the best possible product.

Conception & Production

- Tool design and engineering: Mould design office.

- Technology : Serial mould, thermoplastic injection moulding.

- Material : PA66 30% glass fiber filled.

- Production : 2000 parts

- Tiptoe and heel.

- Presses : 100t et 150t.

- Field : Medical.