Product development : an anti-wolf collar to protect livestock farms

New technology for French breeders

At a time when cohabitation between livestock and wildlife is becoming a crucial issue, Initial has supported the product development of an anti-wolf collar. Designed by CICAL, the collar protects farm animals using a deterrent technology based on ultrasonic and light signals.

CICAL specializes in the development of innovative solutions for the protection of livestock and the cohabitation of wildlife and agricultural activities. It offers robust, high-performance equipment designed to meet the challenges faced by livestock farmers. Committed to an approach combining technology, sustainability and animal welfare, the company implements effective solutions to secure herds against predators, while respecting the surrounding ecosystem.

The anti-wolf collar is based on an ingenious technology: it detects the jolts associated with an attack and instantly triggers ultrasound and flashes of light to repel predators.

Initial played a key role in the product’s design and industrialization.

The aim is to enable farmers to produce and raise their animals, not to spend time protecting their herds. That’s not their job, it’s CAL’s.

Prototyping: a multi-phase approach

The engineering department designed the collar to withstand outdoor conditions, with the design of gaskets guaranteeing optimum sealing, and the design of the electronic integration for optimal collar efficiency.

The prototyping phase was divided into two major stages:

1. Ergonomic powder sintering prototype

Powder sintering technology was selected to produce an initial prototype. This method was used to test and adjust the ergonomics of the collar, ensuring optimum comfort for the animals.

2. Functional vacuum casting prototype

Once the ergonomics had been validated, the vacuum casting workshop produced a functional prototype using materials close to those used in production. This prototype was tested in real-life conditions to validate the collar’s resistance and effectiveness in the face of field constraints.

Industrialization and series production

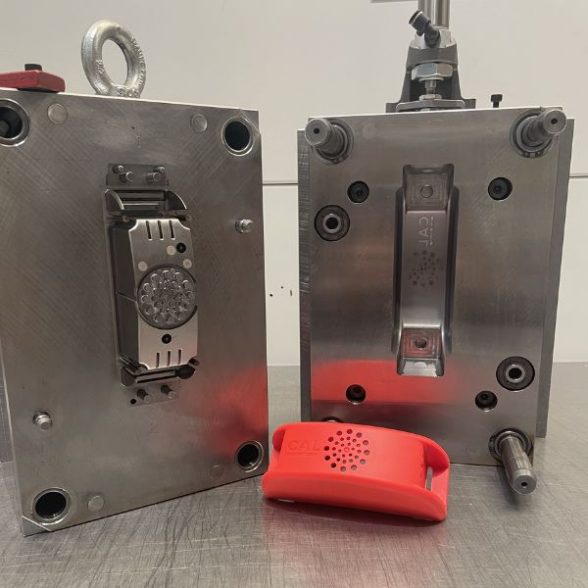

After the test and validation phases, the collar entered the industrialization phase. Thanks to Initial’s design office, the final design was optimized for plastic injection molding. The tooling was also designed by our engineers. This in-house expertise guarantees part quality, precise control of production parameters and efficient mass production.

During the industrialization phase, the PA6 material was selected for series production, thanks to its properties perfectly suited to the collar’s use:

- High mechanical strength: able to withstand repeated shocks and stresses.

- Moisture and UV resistance: essential for a product intended for prolonged outdoor use.

- Enhanced durability: PA6 guarantees optimum longevity, meeting breeders’ expectations for a reliable, high-performance product.

A tried-and-tested system

Today, over 1000 collars have been produced and 560 collars installed, protecting over 4,500 animals.

This project is a perfect illustration of Initial’s product development expertise. Thanks to a combination of innovative technologies, a choice of appropriate materials and complete mastery of injection tooling, we have helped to create a concrete solution for CICAL to protect livestock while respecting wildlife.