SLS 3D printing

Read more

Rapidity

Mechanicals strength

Variety of materials

Manufacturing process

Methodology

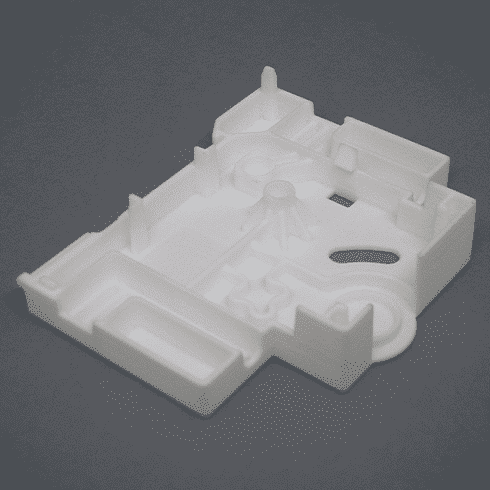

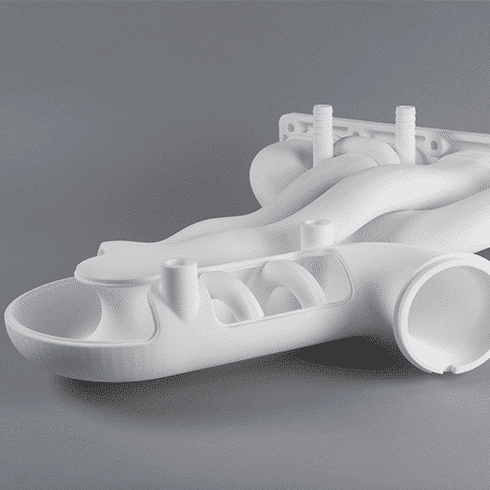

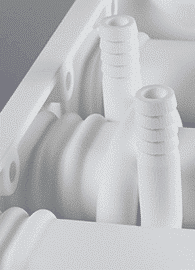

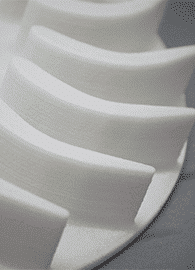

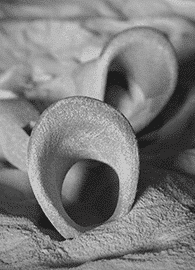

With powder sintering, your parts are created by layering molten polymer under the action of a CO² laser. In a pre-heated chamber, a polyamide-based powder is deposited on a manufacturing platform. An infrared laser beam melts the powder only in the areas corresponding to the part. As the powder solidifies again, the upper stratum attaches to the lower layer, gradually forming the part.

Our strengths

- Extensive machinery

- Wide range of powders

- High productivity

- Optimized costs and lead times

- Operational flexibility: customized processes

- ISO 9001 – EN 9100 certification

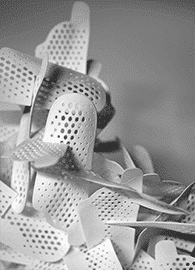

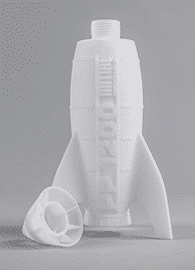

Applications

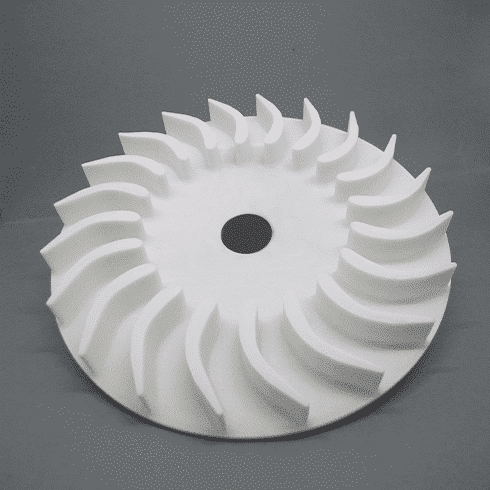

A high-precision rapid prototyping tool. The resulting prototypes feature enhanced resolution thanks to thinner layers and a finer laser spot. Accuracy and detail rendering are considerably enhanced. Ideal for small production runs and the most demanding creations.

Our equipment

4 x EOS® P380 – capacity: 350 x 350 x 600 mm

1 x EOS® P390 – capacity: 340 x 340 x 620 mm

2 x EOS® P730 – capacity: 700 x 380 x 580 mm

1 x EOS® P770 – capacity: 700 x 380 x 580 mm

1 x EOS® P396 – capacity: 350 x 350 x 600 mm

2 x Prodways ProMaker P1000 – capacity: 300 x 300 x 300 mm

1 x Prodways ProMaker P1000X – capacity: 300 x 300 x 360 mm

Our materials

- PA 2200

- PA 2210 FR

- PA 2241 FR

- PA 3200 GF

- PA11 BIO-BASED

- PP 1200

- TPU 70A

- ALUMIDE

-

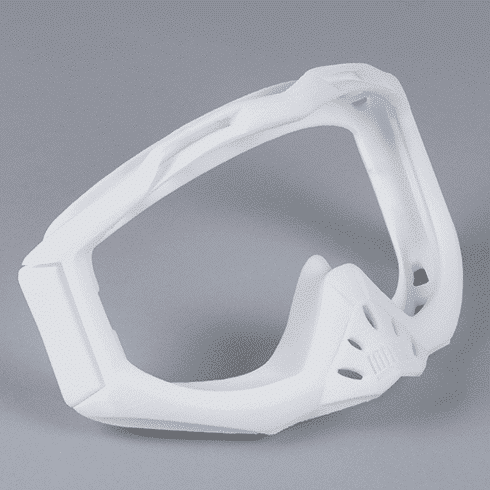

PA 2200

PA 2200 is a polyamide (nylon) powder material often used for the manufacture of final parts or prototypes.

Download the data sheetProperties- Color: white

- Polyamide type PA12

- T° resistance: 130° C

Advantages- Mechanical features

- Low cost

- Flexible, ideal for clips

Limitations- Porous

Accuracy- Layer = 0.12 (P730) or 0.15 mm

- Minimum wall thickness = 0.8 mm

-

PA 2210 FR

PA 2210 FR is a polyamide (nylon) powder material reinforced with mineral fillers to increase its fire resistance.

Download the data sheetProperties- Color: beige

- Self-extinguishing polyamide

Advantages- Aeronautical parts

- Certifications UL 94/V-0/FAR 25

Limitations- Porous

Accuracy- Layer = 0.15 mm.

- Certifications thickness 2mm

-

PA 2241 FR

PA 2241 FR is a polyamide (nylon) powder material reinforced with glass fibers to improve mechanical strength and rigidity.

Download the data sheetProperties- Color: white

- Self-extinguishing polyamide

Advantages- Aeronautical parts

- AR 25/CS 25/JAR25 certifications

Limitations- Porous

Accuracy- Layer = 0.15 mm.

- Certifications thickness 2mm

-

PA 3200 GF

PA 3200 GF is a glass-bead-reinforced polyamide powder material characterized by high rigidity and good elongation at break.

Download the data sheetProperties- Color White-gray

- Imitation PA6.6 FV30

Advantages- Lightweight

- Resistant

Limitations- Rigid

Accuracy- Layer = 0.15mm

- Minimum wall thickness = 0.8mm

-

PA11 BIO-BASED

Biobased PA11, also known as biobased nylon 11, is a thermoplastic polymer produced from renewable raw materials (castor oil).

Download the data sheetProperties- Color: Creamy white.

- High ductility.

Advantages- Impact resistance.

- Mechanical resistance.

Limitations- Porous

Accuracy- Accuracy – Layer: 0.1mm

- Minimum wall thickness: 0.8mm

-

PP 1200

PP 1200 is a polypropylene-based powder. Unlike commonly used polyamides, it offers excellent plasticity, high elongation, low moisture absorption and high durability.

Download the data sheetProperties- White, slightly translucent.

- Flexible.

- Close to injection-molded material.

Advantages- Very good impact resistance.

- Good elongation.

- Good welding capabilities.

Limitations- Surface finish.

- Accuracy.

Accuracy- Layer: 0.1 mm

- Recommended wall thickness > 1 mm

-

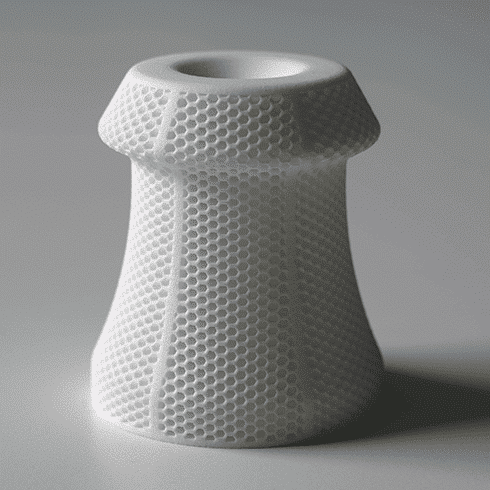

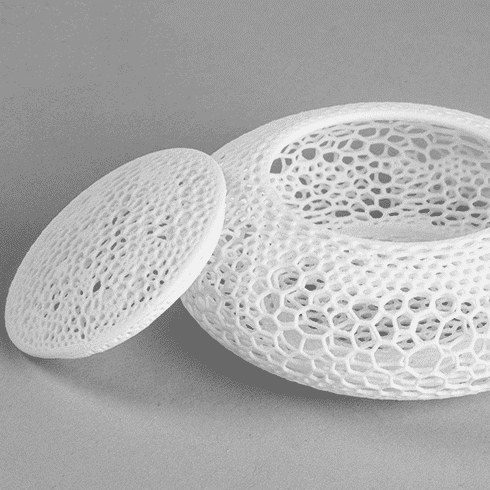

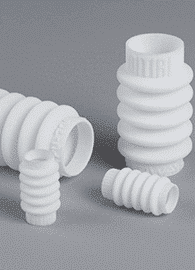

TPU 70A

TPU 70A powder is an elastomer-type material. Its excellent elongation capacity enables ultra-flexible objects to be printed with a very high level of precision and resolution.

Download the data sheetProperties- Flexible.

- 78-80 shA.

Advantages- Close elastomer good material.

- Good chemical resistance

Limitations- Rough surface finish

Accuracy- Layer: 0.1 mm.

- Wall thickness > 1.5 mm.

-

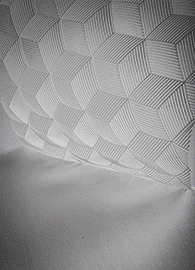

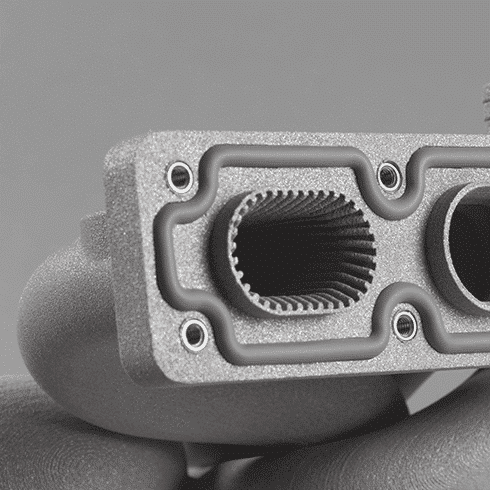

ALUMIDE

Alumide is a composite material combining aluminum powder and polyamide resin (nylon). It is known for its lightness and strength.

Download the data sheetProperties- Color: Aluminum gray

- Metallic appearance

Advantages- Easy to machine

- Good stability

Limitations- Porous

Accuracy- Layer = 0.15mm

- Minimum wall thickness = 0.8mm

Comparison of 3D technologies and plastics

Do you know which material is the most suitable for your 3D printing project?

View our comparison or why not get in touch with us.