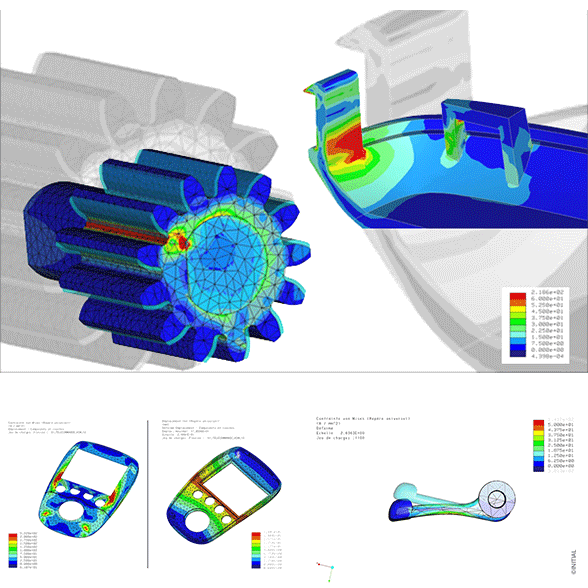

Digital simulation

FEA (Finite Element Analysis)

Our dedicated Simulation unit

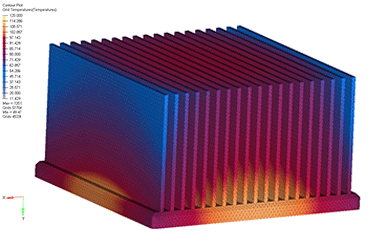

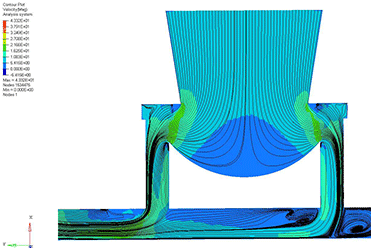

INITIAL can help you generate an authentic representation of how your parts and products behave.Digital simulation is also referred to as Finite Element Analysis (FEA), a way to generate a virtual simulation of a product in its final environment and thereby address multiple industrial challenges, such as predicting design pitfalls, reducing the number of prototypes and even encouraging innovation.

We put our computation skills at your service, whether on projects developed under your care or by direct application in the design process we undertake for you.

- Validate solutions using FEA: minimise risks during the design process.

- Simulate and predict part behaviour using the CAD file.

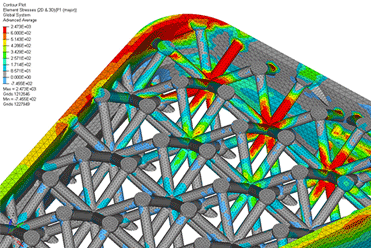

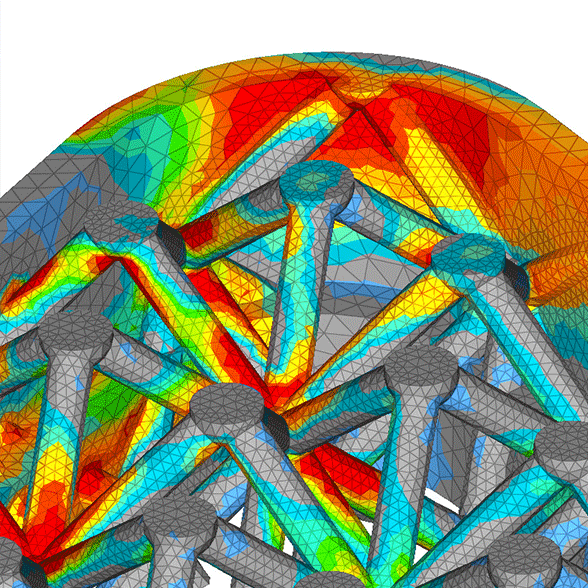

- Make parts lighter by incorporating lattice structures.

- Re-design a part following the identification of a shearing zone and/or optimise a feature.

When is FEA appropriate?

In the course of product development, FEA can be used at various stages of the project.

In general, FEA is done either:

- in pre-project mode, to pre-dimension the part to define its space requirements or ensure its feasibility.

- Following prototype tests, to optimise behaviour or strength.

- After operating tests on the serial product.

- To correct a post-production defect.

We can:

- re-design your parts to build them via plastic or metal additive manufacturing,

- define stress points and load cases for parts,

- recommend a particular production process.

Technical expertise

Technical expertise

INITIAL uses the ABAQUS® solution to deliver all its simulation services.The ABAQUS® environment together with our 3D model generated using the Creo® software offers generous flexibility to optimise part geometries.

- Know-how in plastic materials related to our specialist activity.

- Advice in selecting appropriate materials.

- We incorporate the production constraints of the part in the dimensioning stage or during optimisation.

- Expertise in the additive manufacturing sector.

DELIVERABLES

- Detailed summary report with interpretation of results.

- 3D model of optimised part.

- Recommendations for choice of materials.

Simulation and prediction of part behaviours.