Metal sintering meets medical innovation

Collaboration

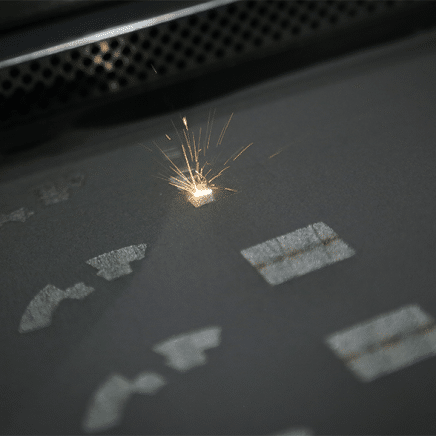

Additive manufacturing by laser sintering, an innovative technology for the medical sector.

Could you tell us about Initial?

O.H: Initial’s DNA could be summed up as innovation, acceleration and production. Today, we are proud to support our customers on the path of innovation. Initial has been in existence for thirty years now, with 100 employees and 60 different production processes. Initial also benefits from ISO 9001 and EN 9100 certification. All this allows us to offer our customers a bespoke experience. This ranges from a straightforward service to end-to-end support with product development projects.

Could you introduce yourself and tell us about your core business?

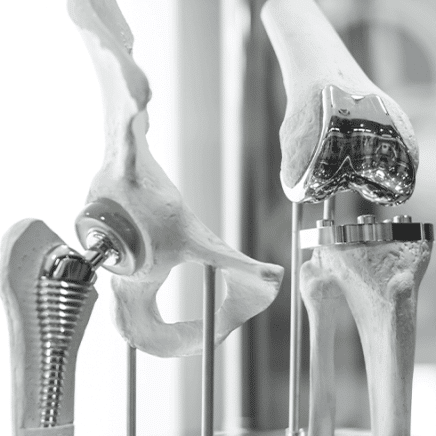

O.N: EDAP TMS celebrated 40 years in business last year. We manufacture urology operating theatre equipment.

We previously had 2 product ranges. A first range of lithotripters used for breaking up kidney stones. We now also have a second range, High-Intensity Focused Ultrasound (HIFU). This technology was initially developed to treat prostate cancer.

How did the idea of incorporating additive manufacturing into your project come about?

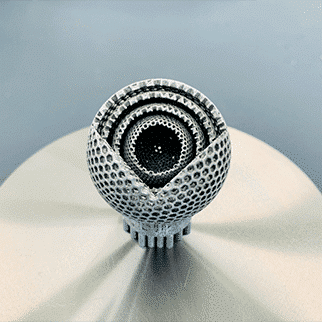

O.N: Originally, these parts were machined. However, as technology was incorporated, we needed to gain access, as well as to improve cooling. Over time, it became increasingly impossible to machine these parts, as there was no longer anything to be gained. It was essential to find an alternative, to improve access and efficiency, in order to increase cooling. The idea of making these parts by metal sintering emerged little by little.

How did initial respond to edap tms’ enquiry?

O.H: Initially, we produced prototypes. These were not intended to be operational, but to be used as the basis for approving a design and dimensions. Originally, these parts were made using stereolithography and polyamide powder sintering. The need then emerged to make metal parts.

Could you tell us more about the metal sintering technology used?

O.H: Metal laser sintering allowed us to meet this need, as it enables shapes and functions to be created, which we are unable to achieve using conventional processes. For example, cooling channels have very specific shapes that are impossible to produce by machining.

Who is this product intended for?

O.N: This product is used by urologists, but, ultimately, it is the patients who benefit, particularly in the case of prostate cancer treatment. Over time, it may be possible to use this technology to treat other conditions such as endometriosis, liver cancer or pancreatic cancer. These treatments are only at a clinical stage, but the prospects look extremely promising.

Address the challenges of innovation and competitiveness with medical 3D printing.

Would you like to increase your knowledge of and expertise in the development of technically complex products? Benefit from the responsiveness of 3D printing with Initial.