Metal 3D printing

Read more

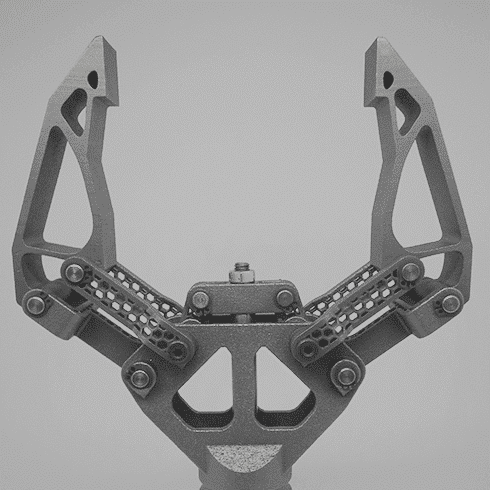

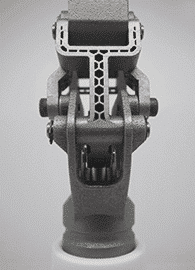

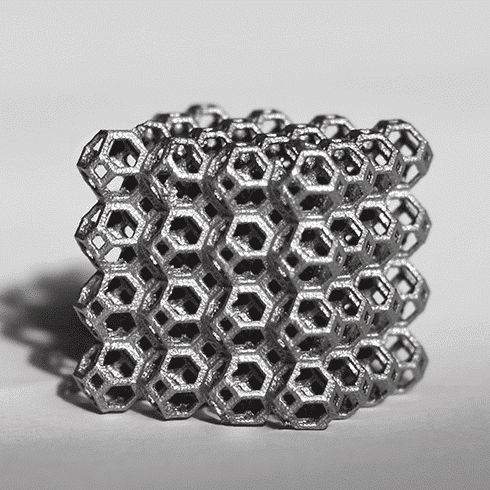

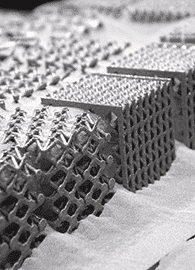

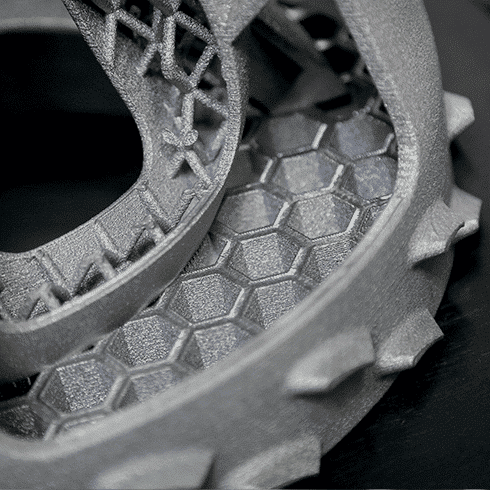

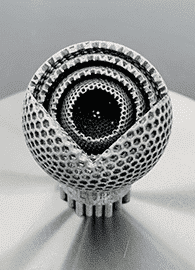

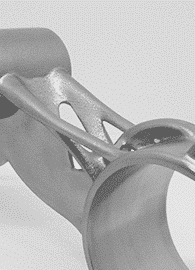

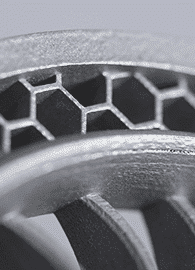

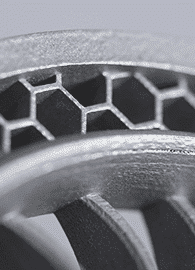

Freedom of shape

Single or series production

Mechanical characteristics

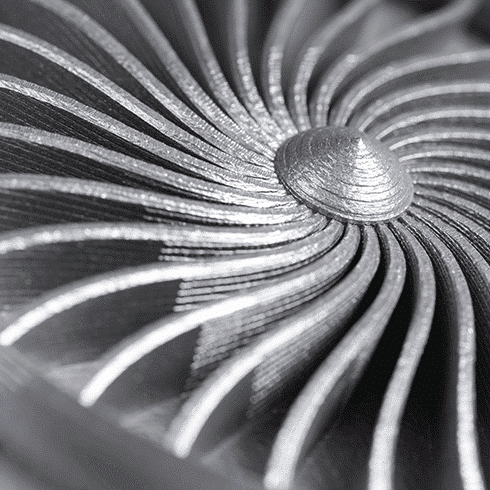

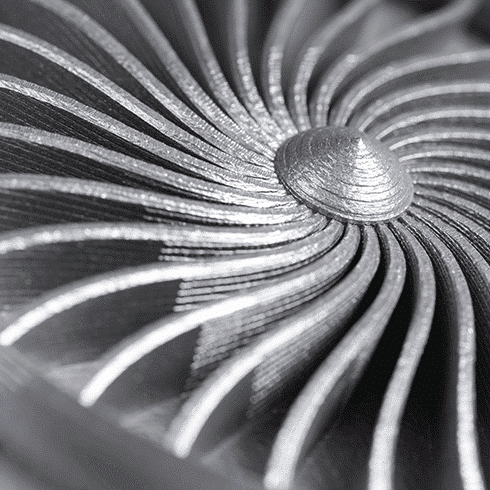

Manufacturing process

Methodology

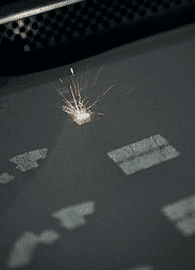

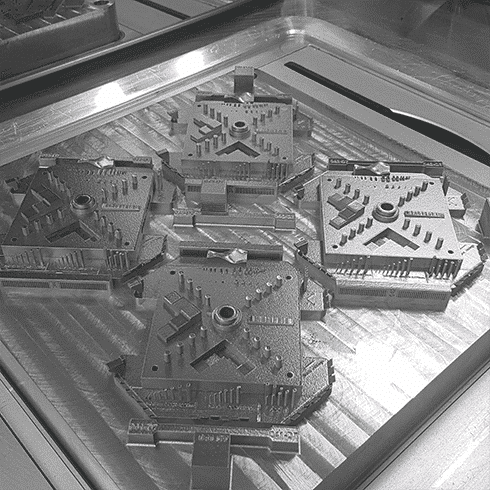

Metal fusion is an additive manufacturing technology that works layer by layer by fusing very thin layers of metal powder with a laser. Metal powder balls melt locally at the point of impact of a laser beam. As they resolidify, they form a horizontal layer and are fused to the layer below.

Our strengths

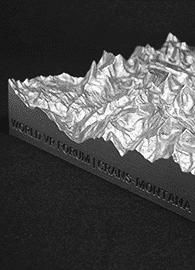

- Create parts with internal and external complexity.

- Produce functional parts.

- Apply a logo/branding to the part for traceability.

- Geometric control.

Applications

- Single or mass production.

- Complex monobloc parts.

- Impossible-to-machine geometries.

- Conformal Cooling: Thermal regulation.

Our equipment

- 1 EOS® M270 – capacity: 250 x 250 x 215 mm

- 1 EOS® M270 Xtended – Capacity: 250 x 250 x 215 mm

- 2 EOS® M280 – Capacity: 250 x 250 x 325 mm

- 2 EOS® M290 – Capacity: 200 x 250 x 325 mm

- 1 EOS® M400-4 – Capacity: 400 x 400 x 400 mm

Our technical materials

- STAINLESS STEEL PH1

- STAINLESS STEEL 316L

- TITANIUM

- COBALT/CHROME

- INCONEL IN718

- ALUMINIUM Alsi10Mg

- ALUMINIUM Alsi7Mg

- MARAGING MS1

-

STAINLESS STEEL PH1

INOX PH1 is a stainless steel that produces durable, high-surface-quality parts for aerospace and automotive applications.

Download the comparison chartProperties- 1.4540 (EU classification)

- Part height: 180 to 200 mm

- T Platform: 250 x 250 mm

- Z-stroke: 220 mm

Advantages- Mechanical characteristics

- Magnetic

- Post-treatment possible

- Corrosion resistance

Limitations- Anti-corrosion

- Medical food contact

Accuracy- Layers 20 and 40 μm

- Density 7.8

-

STAINLESS STEEL 316L

Inox 316L is a stainless steel used to produce corrosion-resistant parts with high toughness, ductility and resistance to acids. This combination is ideal for a wide range of applications in many sectors: medical, industrial, aerospace, automotive and watchmaking.

Download the comparison chartProperties- 1.4404 (EU classification)

- Workpiece height: 280 mm to 300 mm

- T Platform 250 x 250 mm

- Z-stroke: 400 mm

Advantages- Corrosion resistance

- No cytotoxic concentration

- Non-magnetic

- Post-treatment possible

Limitations- Temperature resistance

- Mechanical properties

- Medical food contact

Accuracy- Layers: 20 and 40 μm

- Density: 7.9

-

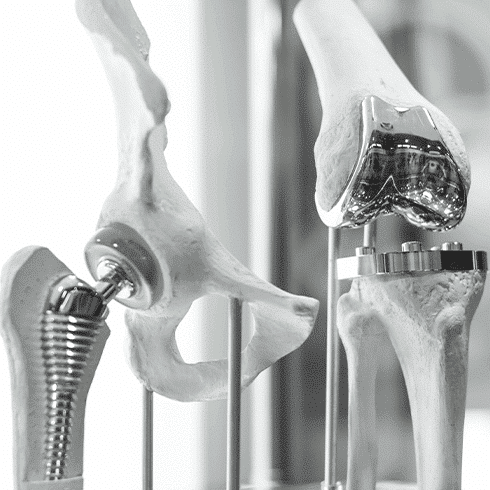

TITANIUM

Titanium is a light alloy with excellent mechanical properties and corrosion resistance, while being lightweight and biocompatible. Its properties are ideal for many high-performance applications in the aerospace, automotive and medical sectors.

Download the comparison chartProperties- Bio-compatible

- Workpiece height: 280 mm to 300 mm

- T platform: 250 x 250mm

- Z-stroke: 328 mm

Advantages- High corrosion resistance

- Good mechanical properties

- Low weight

- Post-treatment possible

Limitations- Temperature resistance

Accuracy- Layers 30 and 60 μm

- Density 4.4

-

COBALT/CHROME

Chrome Cobalt is a nickel-free alloy used for the production of spare parts, functional prototypes, small series or mechanical parts. The parts feature good corrosion resistance and high mechanical properties, even at high temperatures.

Download the comparison chartProperties- Type MP1

- Workpiece height: 180 mm to 200 mm

- T platform : 250 x 250mm

- Z-stroke: 220 mm

Advantages- High temperature

- Biocompatible

- Sterilizable

Limitations- Deformation risk

Accuracy- Layers 20 and 40 μm

- Density 8.29

-

INCONEL IN718

Inconel produces parts with good tensile, fatigue, creep and fracture resistance at temperatures up to 700°C, making them ideal for many high-temperature applications.

Download the comparison chartProperties- Type IN718

- Max. part height: 180 to 200 mm

- T platform: 250 x 250 mm

- Z-stroke: 220 mm

Advantages- Mechanical properties

- Corrosion resistance

- Cryogenic properties

- Temperature resistance

- Post-treatment possible

Limitations- Medical food contact

Accuracy- Layers 20 μm

- Density 8.15

-

ALUMINIUM Alsi10Mg

Printed aluminum parts offer good strength, hardness and dynamic properties. Aluminum is a high-strength, low-weight metal that combines excellent mechanical and thermal properties.

Download the comparison chartProperties- Type AlSi10Mg

- Max. workpiece height: 280 to 300 mm

- T platform: 250 x 250mm

- Z-stroke: 328 mm

Advantages- Robustness and hardness

- Thermal properties

- Low weight

- Post-treatment possible

Limitations- Medical food contact

- Mechanical properties

- Temperature resistance

Accuracy- Layers 30 and 60 μm

- Density 2.7

-

ALUMINIUM Alsi7Mg

Printed aluminum parts offer good strength, hardness and dynamic properties. Aluminum Alsi 7Mg is an anticorrosion, high-strength, low-weight metal that combines excellent mechanical and thermal properties.

Download the comparison chartProperties- Type AlSi7Mg

- Max. workpiece height: 280 to 300 mm

- T platform: 250 x 250mm

- Z-stroke: 328 mm

Advantages- Robustness and hardness

- Anticorrosion

- Thermal properties

- Low weight

- Post-treatment possible

Limitations- Medical food contact

- Mechanical properties

- Temperature resistance

Accuracy- Layers 30 and 60 μm

- Density 2.7

-

MARAGING MS1

Maraging type MS1 is a tool steel. The parts have excellent mechanical properties and can be easily heat-treated through a thermal hardening process to achieve excellent hardness and strength.

Download the comparison chartProperties- 1.2709 (EU classification)

- Maximum workpiece height: 350 mm

- Platform T: 400 x 400cm

- Z-stroke: 400 mm

Advantages- Impact resistance

- Mechanical properties

- High hardness

- Magnetic

- Post-treatment possible

Limitations- Medical food contact

- Corrosion

Accuracy- Layers 20 and 40 μm

- Density 8

Do you have a metal 3D project?

Find out how to go about switching to metal additive manufacturing!

View our technical data sheet or why not get in touch with us.