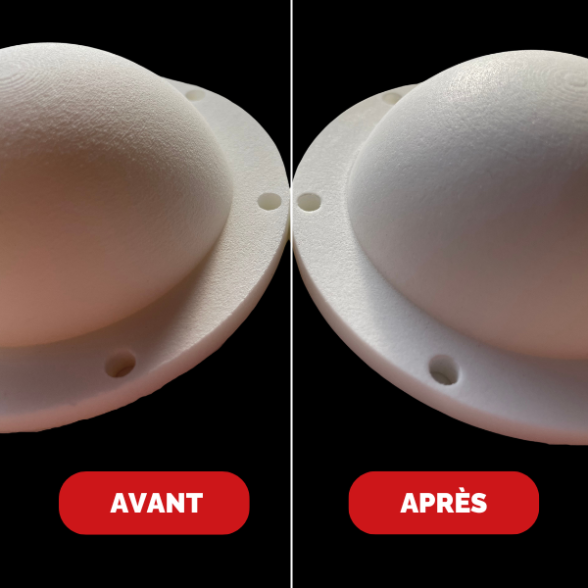

Tribofinishing service: improve the surface finish of your plastic parts

Tribofinishing: a technology at the service of your projects

Initial, expert in additive manufacturing and industrial solutions, is expanding its offering with a new tribofinishing service integrated into its finishing workshop. This mechanical polishing technology enables :

- Polish part surfaces.

- Eliminate burrs and correct irregularities.

- Homogenize surfaces for a more uniform finish.

- Improve aesthetic or mechanical properties.

This step transforms your raw parts into finished products ready for use or sale.

The principle of tribofinishing

Tribofinishing is based on mechanical friction between the parts to be treated and an abrasive medium (granules, ceramics, stones, etc.) in a vibrating or rotating machine. This friction removes roughness, rounds edges and polishes the surface.

Process steps

- Loading:

Parts are placed in a tank containing a mixture of abrasive mediums and possibly chemical additives (cleaning or polishing agents).

- Mechanical movement:

The tank vibrates or rotates, causing continuous movement of the parts and abrasives, resulting in friction.

- Mechanical action:

Abrasives lightly attack the surface of workpieces, enabling them to :

-

- Remove burrs or manufacturing residues.

- Smooth the surface.

- Provide a polishing effect where necessary.

- Rinsing and drying :

Once treatment is complete, parts are rinsed to remove abrasive residues, then dried.

This process offers a high-performance post-treatment solution for improving part quality, both aesthetically and functionally.

Initial: a complete post-processing service

By integrating this technology into its finishes workshop, Initial offers complete project management, from design to manufacturing and post-processing. You benefit from global expertise and personalized support to transform your ideas into finished products.