About us

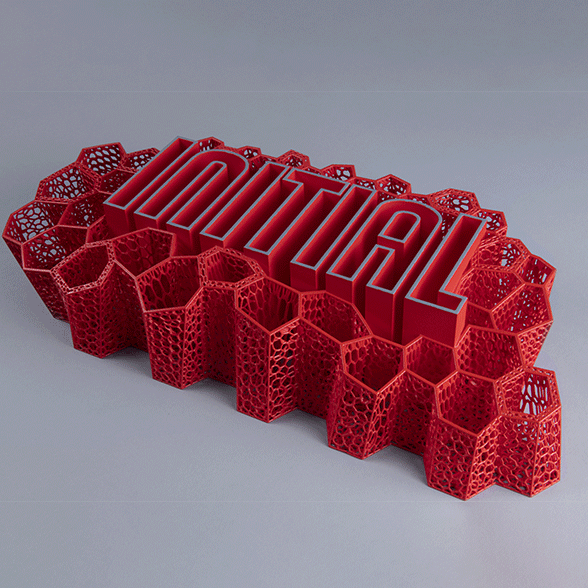

Initial, Prodways Group

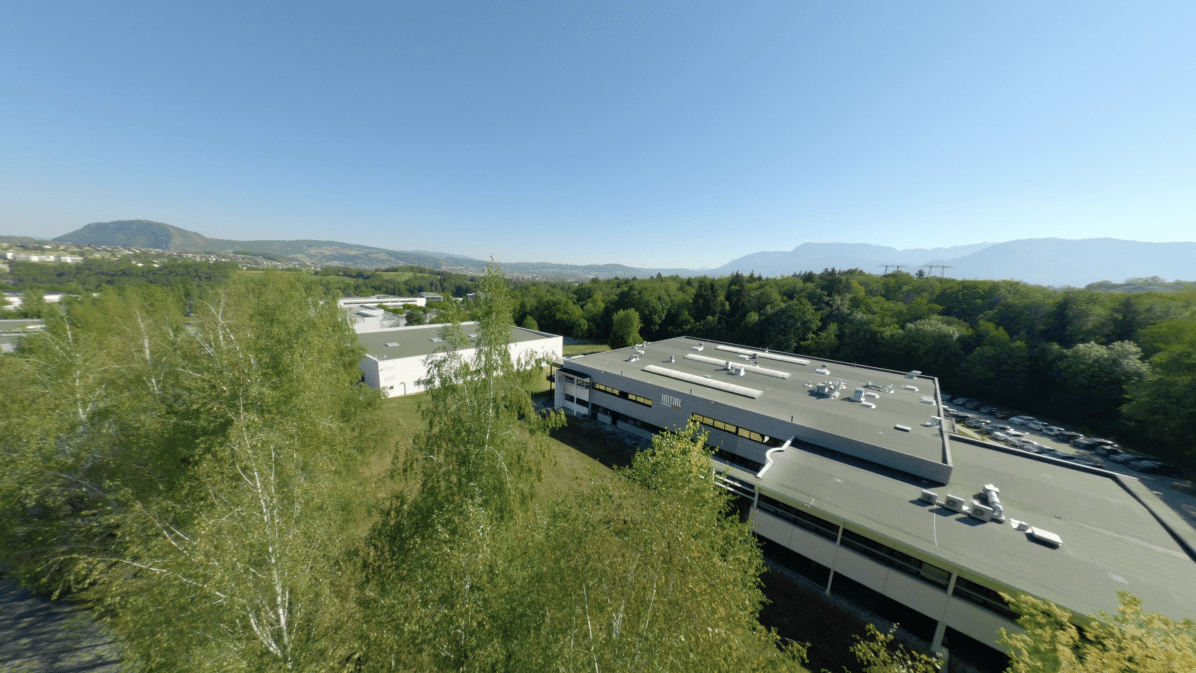

A fascinating immersive drone tour of our production plant.

Leading French industrial player

Welcome to a company where the key words are expertise, innovation and customer satisfaction!Our aim is to deliver a global turnkey solution offering expertise and competitiveness.

This is the challenge that our teams face every day!

View our roadmap:

- Analyse and design your parts

- Produce your parts

Partner for your projects

Our ambition is to generate real added value for you

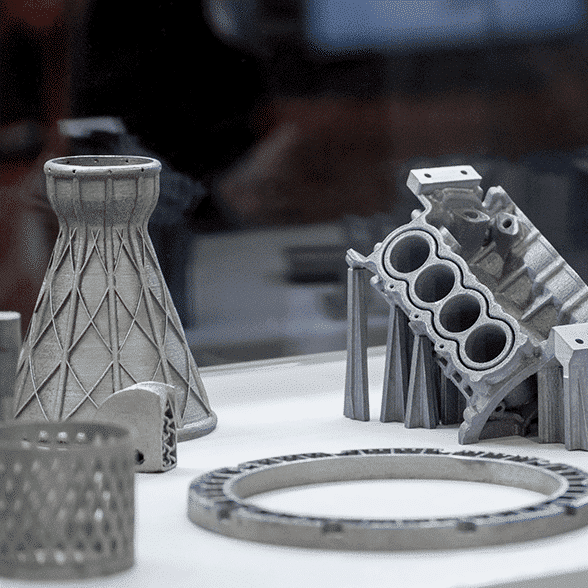

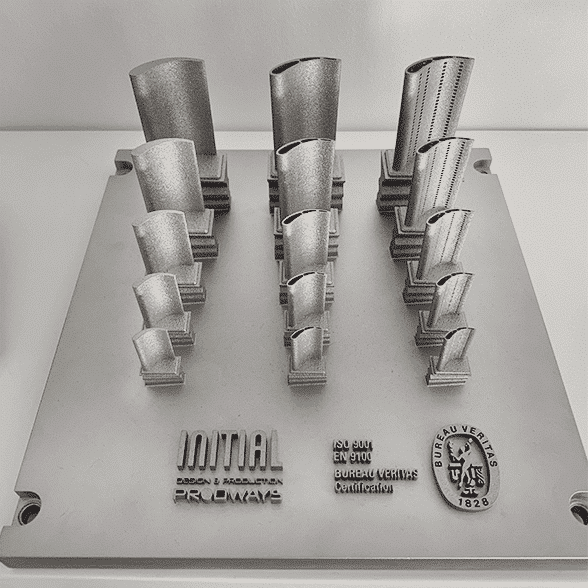

From the proper integration of your needs to delivering appropriate and original solutions, INITIAL Prodways stands out by developing rapid, innovative plastic and metal prototyping solutions alongside a singular production capacity.

Our large machine fleet and our expertise in multiple technologies ensure immense flexibility and optimal reactivity which reduce time to market.

This specific know-how allows us to serial-produce and support market introductions for anything between 1 and 100,000 parts.

We are committed to being by your side every step of the way to guide you to the technological choices best suited to your requirements and objectives.

Creation of Initial

Initial joined Prodways Group

IPO for Prodways Group

Employees

Production plant

INITIAL, a success story

Acquire a fleet of innovative machines

INITIAL quickly developed its fleet of machines with the acquisition of a Renishaw digitizing machine in 1996, followed by the first Stereos 400 stereolithography machine for 3D printing in 1997.

- In 2001, in response to strong growth, INITIAL moved to new premises in Seynod.

- 2002 was marked by the introduction of the “rapid tooling” activity with the creation of a metal mould production workshop.

The objective is to provide its customers with a global service offering from design to industrial-scale production. - In 2003, INITIAL continued its pioneering journey with the acquisition of an EOSint M250 metal sintering machine to make mould cavities, and then the first metal melting machine (DMLS®) M270 to melt maraging steel.

- INITIAL is resolutely oriented to rapid manufacturing or “e-manufacturing”, depending on a quality management system which achieved ISO 9001 certification in 2008.

- In 2011, INITIAL celebrated its 20th anniversary with 50 employees.

It has become a European-scale company and a major player in rapid prototyping.

Becoming a leader in 3D printing

- In 2020, to support its growth, INITIAL moved its headquarters and all R&D and production activities to new premises in Annecy-Chavanod (Haute-Savoie, France) in the Parc Altaïs, thus becoming a centre of excellence within the group.

- Innovation continued throughout the company and 2021 was marked by the development of the new “3D molding” technology , which combines tools manufactured using 3D printing and injection moulding.

- The same year, INITIAL also acquired Creabis GmbH, a German specialist in 3D printing services for plastics.

- Among the recent initiatives deployed by Initial is a complete range of training courses and workshops dedicated to additive manufacturing, designed to support customers in their innovation process.

Efficient production resources

Serving productivity and flexibilityLocated in Chavanod, near Annecy, INITIAL is at the heart of one of the most dynamic regions for business in France.

Near the borders with Switzerland and Italy, the company is just 30 minutes from Geneva airport and 1 hour from Lyon airport.

Innovation serving industry… and people

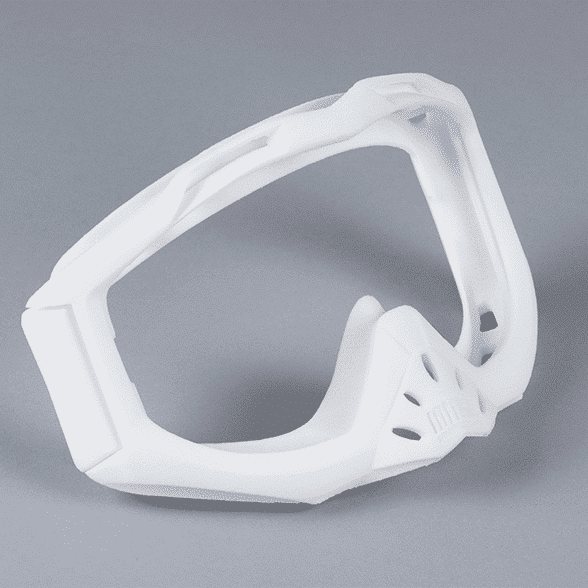

INITIAL works with its customers on exclusive projects in a wide range of industries, such as aerospace, defense, watchmaking and automotive… but not just these!

INITIAL also offers 3D printing solutions specific to medical use, enabling a sector that is constantly evolving and seeking more innovative tools, to manufacture ultra-customised surgical equipment which can be adapted to the specific requirements and morphology of patients.

The company’s know-how has also made it possible to manufacture 45 characters for the animated film “Ma vie de Courgette” (My Life as a Courgette)!

A committed quality process focused on customer satisfaction

Quality management is key to the success of INITIAL Prodways.

From marketing to production, the know-how and commitment of all our employees ensure they make enormous efforts every day to satisfy our customers.

The company holds certifications for all of its activities, a guarantee of impeccable quality processes:

- ISO 9001 certification.

This defines the steps required for a quality management system with the objective of constantly improving a response to customer needs and expectations. - EN 9100 certification.

This guarantees expertise in manufacturing processes, traceability, and the supply chain that are specific to the aerospace and defense market.