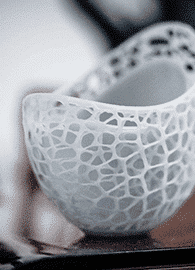

FDM 3D printing

Read more

Variety of materials

Large parts

Cost-effective

Manufacturing process

Methodology

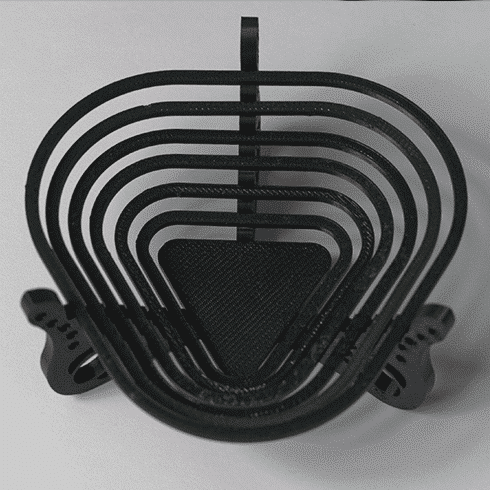

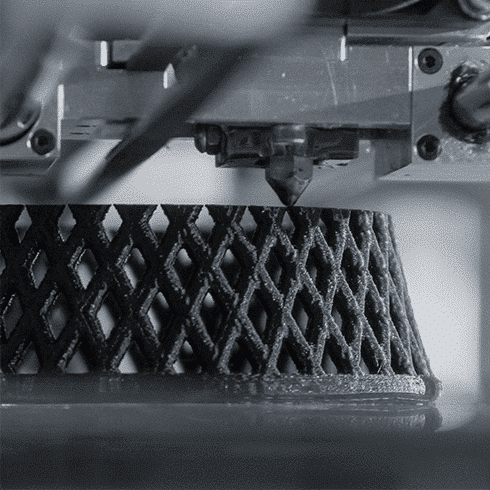

FDM (Filament deposition manufacturing) involves melting a thermoplastic wire through a nozzle heated to high temperature. The molten filament (of the order of a tenth of a millimeter) emerging from the nozzle is laid down in line, and bonds to what has already been laid down. The part is built by depositing a molten filament extruded by a heated nozzle guided by CAD data.

Our strengths

- Professionals who listen

- Technical expertise

- Proposal-driven

- ISO 9001 – EN 9100 certification

Applications

- Test your prototypes

- Manufacture durable, high-stability parts

- Production of educational tools

- Jig production

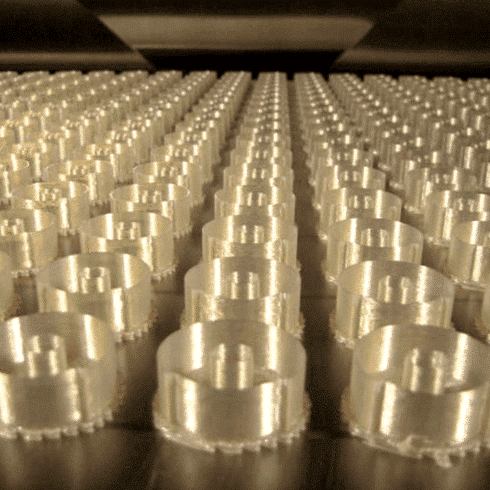

Our equipment

- 1 STRATASYS Fortus® 900MC – capacity: 914 x 610 x 914mm

- 1 STRATASYS Fortus® 450MC – capacity: 406 x 355 x 406mm

Our materials

- NYLON 12CF

- ABS M30

- ABS ESD7

- POLYCARBONATE

- ULTEM®

-

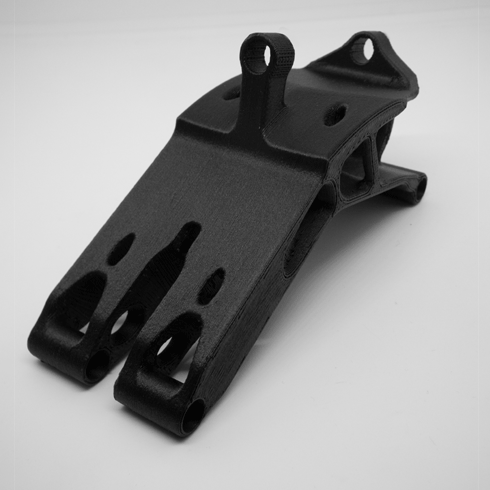

NYLON 12CF

Download the data sheetFDM Nylon 12 Carbon Fiber (Nylon 12CF) combines Nylon 12 with carbon fibers to achieve a flexural strength and strength-to-weight ratio superior to any FDM material. Validate designs faster with functional carbon fiber prototypes. Replace heavy metal tools with lighter, more ergonomic Nylon 12CF tools.

-

ABS M30

ABS M30 is an engineering thermoplastic known for its strength, robustness, lightness and resistance. This material is ideal for form and fit checks, as well as for prototyping functional parts.

Download the data sheetProperties- Ivory

- Black

- Red

- Other shades on request.

Advantages- Certifications : UL 94 / -HB

- Good dimensional stability

Limitations- Surface finishes

Accuracy- Layer = 0.178 to 0.33 mm

- Recommended wall thickness = 1.2 mm

-

ABS ESD7

ABS ESD7 is an engineering thermoplastic known for its strength, toughness, lightness and resistance. This material is ideal for form and fit checks, as well as for prototyping functional parts.

Download the data sheetProperties- Black

- Antistatic

Advantages- Certifications : UL 94 / -HB

- Good dimensional stability

Limitations- Surface finishes

Accuracy- Layer = 0.178 to 0.33 mm

- Recommended wall thickness = 1.2 mm

-

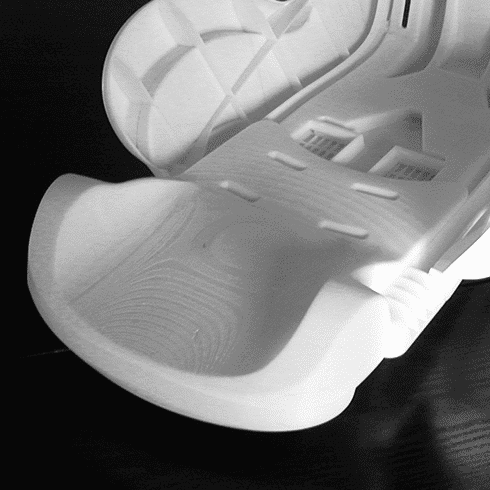

POLYCARBONATE

Polycarbonate (PC) is a material offering precision, durability and stability. It can be used to produce solid parts capable of undergoing functional testing.

Download the data sheetProperties- White

Advantages- Certifications : UL 94 / -HB

- Sturdiness

Limitations- Surface finishes

Accuracy- Layer = 0.178 to 0.33 mm

- Recommended wall thickness = 1.2 mm

-

ULTEM®

ULTEM™ thermoplastic is a high-performance, flame-retardant material characterized by a high strength-to-weight ratio and excellent impact resistance.

Download the data sheetProperties- Gold

- Black

Advantages- Certifications UL 94 / V-0

- Railway standard EN-45545-2

- Heat resistance

Limitations- Surface finishes

Accuracy- Layer = 0.254 to 0.33 mm

- Recommended wall thickness = 1.2 mm

Comparison of 3D technologies and plastics

Do you know which material is the most suitable for your FDM 3D printing project?

View our comparison or why not get in touch with us.