MJF 3D printing

Read more

Isotropic mechanical properties

Appearance

Rapidity

Manufacturing process

Methodology

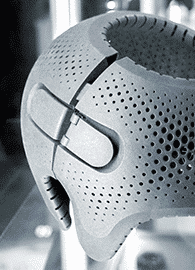

MJF technology is a somewhat hybrid of powder melting and powder bonding, and the MJF printing process begins with the application of a thin layer of powder to the platform. Next, a binding agent and a detailing agent are applied to the powder layer, followed by melting of the parts exposed to the binding agent using a heating device. The parts exposed to the detailing agent remain in powder form, enabling precise definition of part boundaries and dimensional accuracy.

Applications

- functional prototyping

- small series production

- continuous printing

Our strengths

- Good sealing properties depending on geometry

- Best-in-class isotropy

- Simplified, cleaner experience with closed, automated material mixing

- Industry-leading, cost-effective and reusable materials

Our equipment

- 2 HP MultiJet Fusion 4210 machines capacity: 380 x 284 x 380 mm

Our materials

- HP PA12

- HP PA12 GB

-

HP PA12

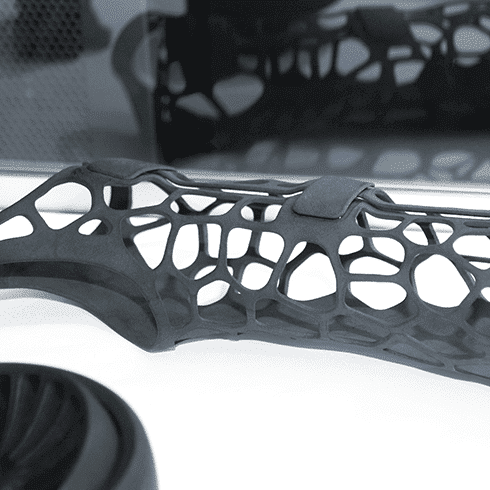

HP PA12 is a thermoplastic material ideally suited to the production of robust, functional, complex and detailed parts.

Download the data sheetProperties- Color: dark gray

- USP Class I and Class VI

- FDA food contact

- Flexible

- Ideal for clips

- T° resistance: 130°C

Advantages- Good isotropic mechanical and dimensional properties

- Functional testing

- Good sealing properties depending on geometry

Limitations- Print lines visible on horizontally produced surfaces.

Accuracy- Layer: 0.08 mm

- Recommended wall thickness > 1 mm

-

HP PA12 GB

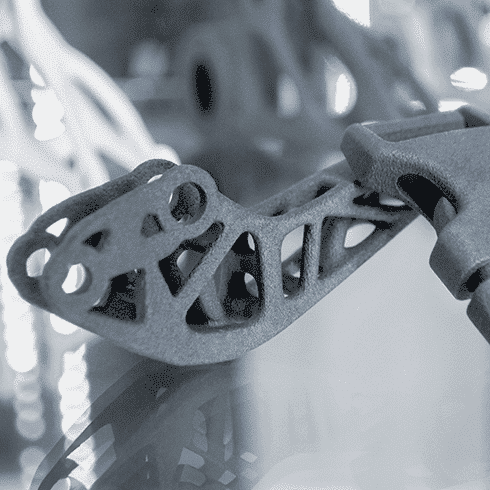

HP PA12 GB is a thermoplastic material composed of 40% glass beads. Ideal for the production of high-quality, rigid parts with optimum dimensional stability.

Download the data sheetProperties- Color: Light gray

- Filled with glass beads

- Rigid

- Good dimensional stability

- T° resistance: 130°C

Advantages- Good isotropic mechanical and dimensional properties.

- Functional testing.

- Good sealing properties depending on geometry.

Limitations- Print lines visible on horizontally produced surfaces.

Accuracy- Layer: 0.08 mm

- Recommended wall thickness > 1 mm

Comparison of 3D technologies and plastics

Do you know which material is the most suitable for your 3D printing project?

View our comparison or why not get in touch with us.