Device for the acquisition and scanning of 3D printing

Scanning feet in 3D

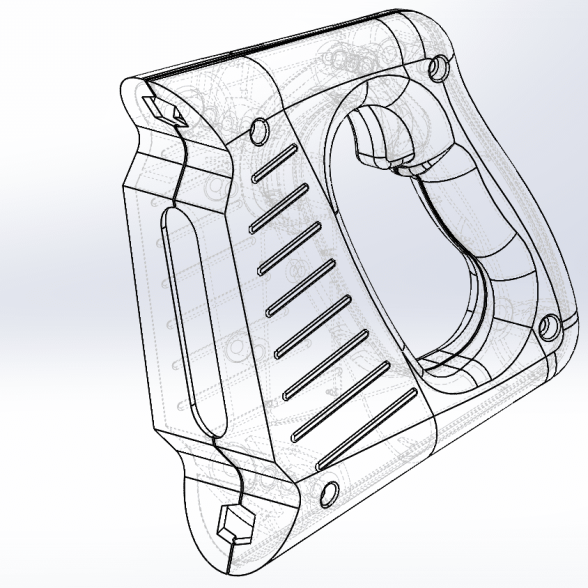

Podoclic®ScientiFeet decided to capitalise on Initial’s 30 years of expertise and to use its design office to develop its innovative project, the

first portable podiatry 3D scanner for taking seated impressions.

Produced in collaboration with the design office and with the aid of vacuum casting technology within Initial.

An innovative alternative

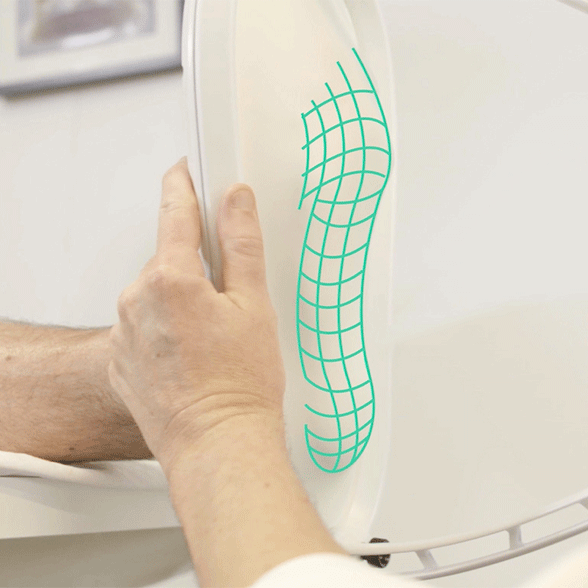

The product needed to be simple and ergonomic, while ensuring a quick turnaround and a reduction in waiting times for patients.

The aim is to capture a foot in a real situation for a more accurate diagnosis, enabling 3D soles, which are perfectly tailored to the needs of each patient, to be designed.

The technical choices

- Prototyping, the design office used SLS technology by powder sintering for its flexibility and speed of implementation.

- Industrialisation, the preferred technology was vacuum casting, in view of ScientiFeet’s required annual volume.

- As regards the choice of plastic (PX 223 resin). The latter was chosen for its resistance to compression stresses, established on the basis of digital simulations.

Feedback

- The design results were extremely satisfactory and entirely met the requirements of the specifications.

- The second result was that expressed by the practitioner.

The latter was also entirely satisfied with the finished product.

In effect, the resulting ease of use and the time saving will enable the practitioner to concentrate on his core business and added value: medical diagnosis.

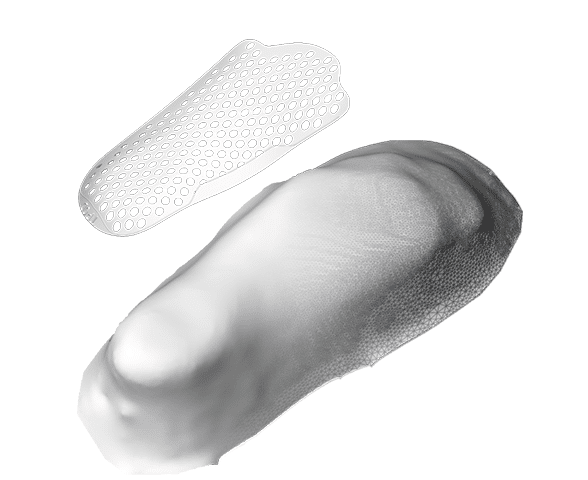

Designing custom-made orthopaedic soles

The scanning data acquired by Podoclic will be used to design customised orthotics by taking account of the unique characteristics of each patient’s feet.

This will allow podiatrists to adjust the size, shape, density and thickness of orthotics to meet the specific needs of each patient.