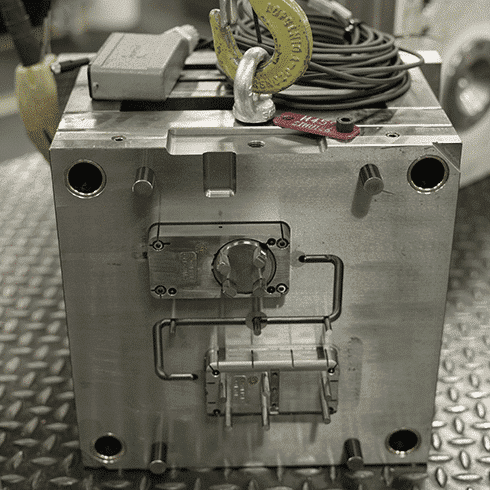

Serial mold

A high quality steel serial mold to manufacture your simple or complex parts. Tooling technology that offers finely-scheduled production.

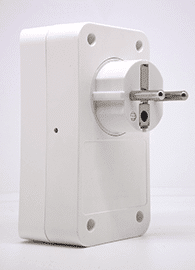

Mass production

Production of 100 to 100,000 identical parts in serial mode based on an annual schedule.

Traceability

Benefit from the traceability of our injection processes and production batches.

Finishes

Wide range of finishes for optimised result: inserts, overmoulding, pad printing, engraving, custom packaging.

INTEGRATED DESIGN OFFICE

Production easily scheduled using series mold

We design your production mould tooling in our dedicated design office:

- CAD layouts to simplify mould production and reduce costs and lead times.

- Integration of the necessary drafts.

- Checking material thicknesses.

- Simulation, in certain cases, of the part’s behaviour during injection.

- Anticipation during tool design: filling, part deformation, hot spots in the mould, etc.

- Our software :

Series mold tooling technology for planned production:

- Product marketing.

- Parts manufactured according to a forecast schedule.

- Tooling guarantee from 500,000 to 1,000,000 parts.

Based on the 3D file of your part, we carry out a tooling study:

- CAD/CAM generation of tool paths and electrodes.

- Machining of cavities.

- Polishing of cavities or specific graining.

- Mould adjustment and assembly.

- Injection testing and tooling fine-tuning (MAP) up to the presentation of initial samples accompanied by an inspection report and capabilities if required.

Production flexibility for your mass-produced parts:

- Management of mould storage and maintenance.

- Annualised production planning.

- Rapid delivery of small quantities.

- Standard injection, capillaries, nozzles or hot blocks.

- Single or multiple cavities.

- Industrialisation of the process according to announced quantities.

Technical expertise

From 100 to 100,000 injection-molded parts

- Series Molding

-

Series Molding

A high-quality steel mold for regular production of your simple or complex serial parts.

Download the presentationSpecifications- Impression blocks mounted in standard INITIAL housing or complete steel mold.

Dimensions- Part size according to analysis and technical validation

- Max volume = <200cm3

- Max. surface area = <300cm3

Matière définitiveAll thermoplastics except PVC.

- PA, PBT, POM, PP: filled and unfilled.

- LCP, PEEK, PEI, PESU, PPA, PPS.

- HDPE and LDPE.

- ABS, ABS/PC, PC.

- PMMA, SEBS, TPE, TPU.

Production lead times- To define according to your project.

- Production file approved by EI.

- Definition of the control range, packaging, etc.

- Production of parts according to an annual schedule.

Comparison of tooling technologies

Do you know if series mould tooling is suited to producing your plastic parts?

View our comparison or why not get in touch with us.